Introduction: Welcome to the Age of Collaborative Robots

In recent years, a revolutionary technology has been quietly transforming factories and workplaces around the world. Collaborative robots, or cobots, are ushering in a new era of human-robot interaction, powered by advances in artificial intelligence (AI) and automation. This blog post will explore the exciting world of cobots, their impact on various industries, and how they’re reshaping the future of work.

What Are Cobots? Understanding the Basics

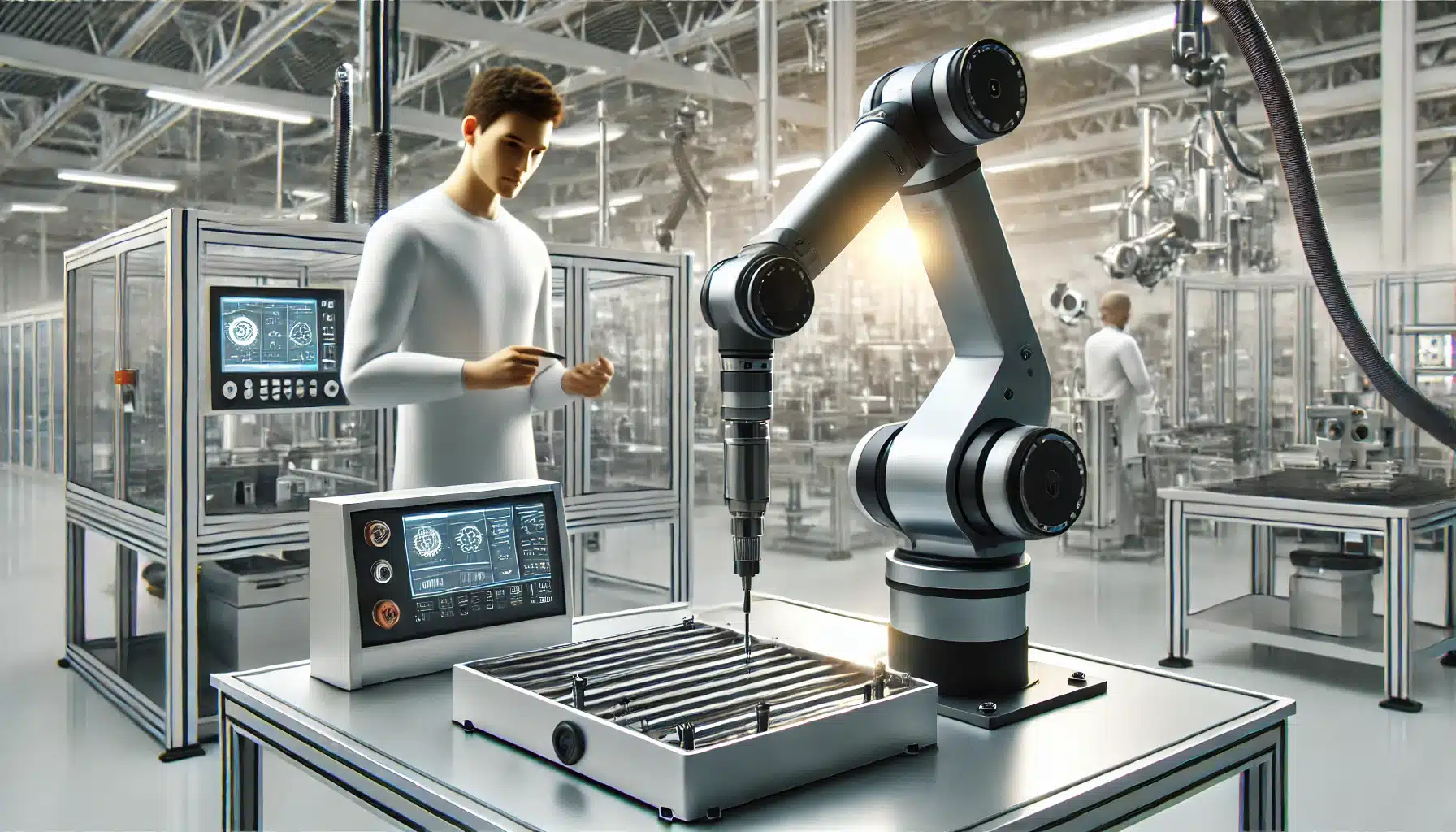

Defining Collaborative Robots

Cobots are a unique class of robots designed to work alongside humans in shared spaces. Unlike traditional industrial robots that operate in isolation, cobots are built with safety features and advanced sensors that allow them to interact directly with human workers. This collaboration between humans and machines is revolutionizing productivity and efficiency in many sectors.

Key Features of Cobots

- Lightweight and portable design

- Built-in safety mechanisms

- User-friendly programming interfaces

- Adaptive learning capabilities

- Versatile end-of-arm tooling

The Evolution of Robotics: From Isolation to Collaboration

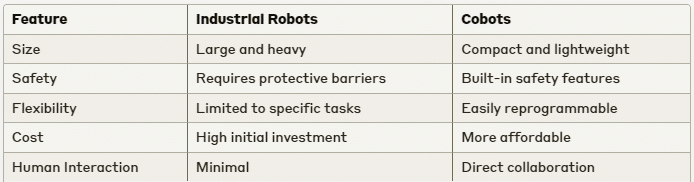

Traditional Industrial Robots vs. Cobots

Traditional industrial robots have been around for decades, but they typically operate in caged environments, separate from human workers. Cobots, on the other hand, are designed to break down these barriers and work hand-in-hand with their human counterparts. This shift represents a significant leap forward in robotics technology and AI automation.

Comparison Table: Industrial Robots vs. Cobots

AI and Cobots: A Perfect Match

How AI Enhances Cobot Capabilities

Artificial intelligence is the driving force behind the advanced capabilities of cobots. Machine learning algorithms allow cobots to adapt to changing environments, recognize patterns, and make decisions in real-time. This integration of AI and robotics is creating smarter, more efficient machines that can truly complement human skills.

Key AI Technologies in Cobots

- Computer vision for object recognition

- Natural language processing for voice commands

- Reinforcement learning for task optimization

- Predictive maintenance algorithms

- Adaptive motion planning

Industries Embracing Cobot Technology

Manufacturing: The Frontline of Cobot Adoption

The manufacturing sector has been at the forefront of cobot integration. From automotive assembly lines to electronics production, cobots are streamlining processes and enhancing productivity. They’re particularly useful for repetitive tasks that require precision and consistency.

Healthcare: Cobots as Medical Assistants

In healthcare settings, cobots are assisting surgeons, helping with patient rehabilitation, and even aiding in the fight against infectious diseases. Their ability to perform delicate tasks with extreme precision makes them invaluable in medical applications.

Logistics and Warehousing: Optimizing Supply Chains

Cobots are revolutionizing warehouse operations by working alongside human workers to pick, pack, and sort items. This collaboration is leading to faster order fulfillment and reduced errors in inventory management.

The Benefits of Cobot Implementation

Enhancing Workplace Safety

One of the primary advantages of cobots is their ability to take on dangerous or ergonomically challenging tasks, reducing the risk of workplace injuries. Their advanced sensors and safety features ensure that they can operate safely in close proximity to humans.

Boosting Productivity and Efficiency

By automating repetitive tasks and working continuously without breaks, cobots can significantly increase production output. This allows human workers to focus on more complex, value-added activities that require creativity and problem-solving skills.

Improving Product Quality

Cobots excel at performing precise, repetitive tasks with consistent quality. This leads to fewer errors and defects in manufacturing processes, resulting in higher overall product quality.

Addressing Labor Shortages

In industries facing labor shortages, cobots can fill the gap by taking on tasks that are difficult to staff. This helps companies maintain productivity even when faced with workforce challenges.

Challenges and Considerations in Cobot Adoption

Initial Investment and ROI

While cobots are generally more affordable than traditional industrial robots, there is still an initial investment required. Companies need to carefully consider the return on investment and long-term benefits when implementing cobot technology.

Employee Training and Acceptance

Introducing cobots into the workplace requires proper training for employees who will be working alongside them. Overcoming resistance to change and fostering acceptance of this new technology is crucial for successful implementation.

Regulatory and Safety Compliance

As with any new technology, there are regulatory considerations to keep in mind when deploying cobots. Ensuring compliance with safety standards and workplace regulations is essential for smooth integration.

The Future of Work: Human-Cobot Collaboration

Redefining Job Roles and Skills

As cobots become more prevalent, the nature of work is evolving. Human workers are shifting towards roles that require higher-level thinking, creativity, and emotional intelligence – skills that complement rather than compete with cobot capabilities.

Continuous Learning and Adaptation

Both humans and cobots will need to engage in continuous learning to keep pace with technological advancements. This symbiotic relationship will drive innovation and push the boundaries of what’s possible in various industries.

Case Studies: Successful Cobot Implementations

Automotive Industry: Precision Assembly

A major car manufacturer implemented cobots on their assembly line to assist with precise fastening tasks. The result was a 20% increase in productivity and a significant reduction in assembly errors.

Pharmaceutical Company: Laboratory Assistance

A pharmaceutical research lab introduced cobots to handle repetitive sample preparation tasks. This allowed researchers to focus on data analysis and drug development, accelerating the research process by 30%.

Common Questions About Cobots

Are cobots safe to work with?

Yes, cobots are designed with multiple safety features and sensors to ensure safe operation around humans.

Can cobots completely replace human workers?

No, cobots are designed to complement human skills, not replace them entirely. They excel at repetitive tasks but still require human oversight and collaboration.

How difficult is it to program a cobot?

Most cobots feature user-friendly interfaces that allow for easy programming, even for those without extensive technical backgrounds.

What industries can benefit from cobot technology?

Cobots can be beneficial in a wide range of industries, including manufacturing, healthcare, logistics, agriculture, and more.

How does AI contribute to cobot functionality?

AI enables cobots to learn from experience, adapt to new situations, and make decisions based on real-time data, enhancing their overall performance and versatility.

Conclusion: Embracing the Cobot Revolution

The rise of cobots represents a significant shift in how we approach automation and human-robot interaction. By combining the strengths of both humans and machines, cobots are paving the way for a more efficient, safe, and productive future of work. As AI and robotics technology continues to advance, we can expect to see even more innovative applications of cobots across various industries.

Are you ready to embrace the cobot revolution in your workplace? The future of human-robot collaboration is here, and it’s an exciting time to be part of this transformative journey.